Protecting Test Hardware to Protect Flight Hardware

- By Maggie Masetti

- July 15, 2015

- Comments Off on Protecting Test Hardware to Protect Flight Hardware

The title may seem a little circular, but this is not a story that often gets told – that is, we have to keep our test hardware clean to keep our flight hardware clean.

To that end, a new NASA Goddard tech is being tested out in NASA Johnson’s giant Chamber A, where the James Webb Space Telescope will undergo extreme cold in order to make sure its mirrors and instruments are in working order for use in space. Contamination during assembly and testing, especially from organic materials, is kind of a big deal – thus all the cleanroom suits that workers wear when in proximity to hardware.

Image credit: NASA/Chris Gunn

The photo above shows Nithin Abraham, a Thermal Coatings Engineer from Goddard, placing Molecular Adsorber Coating or “MAC” panels in Chamber A. “The Molecular Adsorber Coating (MAC) is a NASA Goddard coatings technology that was developed to adsorb or entrap outgassed molecular contaminants for spaceflight applications,” said Abraham. (You might be familiar with an example of outgassing called “new car smell.”)

MAC is a (patent-pending!) sprayable paint made of zeolite (a mineral widely used in industry for water purification among other things), and a colloidal silica binder that acts as the glue holding the coating together. This new molecular adsorber is highly permeable and porous, which allows it to trap the outgassed contaminants.

MAC can be used to keep outgassing from coming in from outside areas or to capture outgassing directly from hardware, components, and within instrument cavities. In this case, MAC is helping by capturing outgassed contaminants outside the test chamber from affecting JWST components. MAC is expected to capture the outgassed contaminants that exist in the space of the vacuum chamber. “Although we cannot stop contaminants within the vacuum chamber from outgassing, we can try to capture them with MAC before it tries and reaches the expensive hardware, which are housed inside the test chamber,” Abraham said.

This photo is from May 2015, when several test panels were custom designed and fabricated, and spray coated with MAC for use in Chamber A in preparation for the arrival of the James Webb Space hardware. “The MAC panels were installed in very strategic locations within Chamber A to capture vacuum chamber contamination originating from persistent sources, such as silicone pump oil residue and hydrocarbons,” Abraham said. Some silicone based contaminants are known to outgas and spread easily, even at ambient temperatures, and are extremely difficult to remove and clean.

Ironically, the walls of the chamber have a matte finish, which makes them look unclean, but we promise they are clean! Some areas in the chamber also have markings which indicate where there’s been rubbing from a tool that has slightly burnished the surface.

This is the “plenum” or very bottom of NASA Johnson’s Chamber A:

Image credit: NASA/Chris Gunn

Chamber A looks like this from the outside:

Image credit: NASA

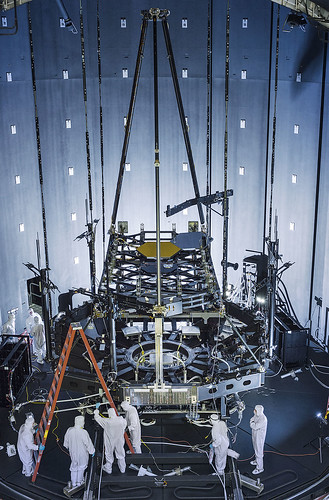

And with our test hardware inside:

Image credit: NASA/Chris Gunn

Read more about MAC in this NASA feature.

If you’re interested in cleanroom suits and what the process of getting ready to go in a cleanroom is like, Laura Betz demonstrates in this video.